If you’re thinking about getting a new set of control arms, you don’t have many complicated questions to answer. You can go with either tubular or boxed arms, choose the design and colour you want, and decide if you’re going to use your car for racing.

But then, what about the bushings? That’s when you can get into some trouble.

Don’t get too overwhelmed, but do give bushings their due. Because they can make or break your build.

The bushings you decide to get will have a direct and noticeable impact on your vehicle’s performance, ride, and comfort. So keep reading if you want to understand why they’re so critical, and how to choose the ones that will work best on your ride.

What’s the Big Deal about Bushings?

Chances are that you’ll get as many different opinions on bushings as the number of people you ask. Everyone has their own take on bushings, and it’s normal – bushings are subjective.

Many factors can influence your own personal preference, and like everything in life, each choice has its own pros and cons. But, really, bushings are a big deal.

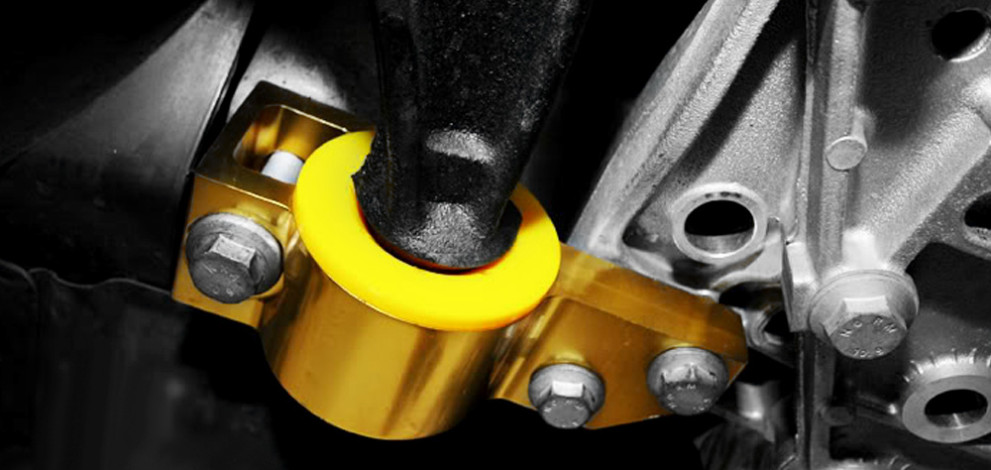

They connect the suspension link and your ride’s chassis with the differential or with the front tires. But more than that, they are the first suspension component to receive the force of torque. Your bushings directly impact your steering input, as well as how your ride deals with the terrain it’s being driven on.

If your bushings are softer than needed, worn out, our outright damaged they will deflect. And this means you’re downright wasting energy. On top of that, this will allow your suspension to move more freely, which means it may shift and throw off the front or rear wheel’s alignment. Ouch.

If your bushings deform under a heavier load, they are absorbing energy instead of transferring it to the chassis. On the other hand, if your bushings are harder they won’t be able to absorb noise, vibration, and harshness (NVH for short). This NVH noise will travel down your chassis and make its way inside your cab. And then it’s up to you to decide what’s tolerable.

Car designers know all of this. But when they were designing your ride’s stock bushings, their top priority was not performance. Car designers care about the lowest possible noise levels, and car designers care about being under budget. That’s why aftermarket bushings can make huge improvements to your stock build.

And if racing is in your blood, you can’t get a true race car feel without soild-mounted rod ends… the price is 100% of the NVH.

Performance Bushings Types

Your stock bushings are made from rubber. Rubber does a great job at absorbing NVH noises, and this will give you a quiet, smooth, conformable ride.

But rubber also is quick and easy to wear down, rip, and deflect.

So, let’s take a look at what else is out there.

Polyurethane Bushings

You’re probably familiar with polyurethane. It’s synthetic and will never rot or wear down from oil, salt, grime, UV rays, or other environmental factors. This material is hard enough to minimize deflection, yet and flexible enough to absorb a good deal of NVH. Polyurethane bushings will perform well under hard acceleration while giving you comfortable handling.

It’s lower cost is also a huge advantage over other bushing martials. And its properties allow it to be molded with varying degrees of hardness (the correct term is durometer). This will allow you to decide on your own what tradeoff you want between performance and NVH.

Delrin Bushings

Delrin is an extremely hard polymer material that refuses to deflect. This material is best suited for one-directional motion where articulation is not a priority, like with IRS cradle bushings and A-arm bushings.

Delrin bushings are less commonly used in rear control arms, where articulation is very important. For those cases, it’s best to go with rod ends or spherical bushings.

Rod Ends and Spherical Bearings

Rod ends and spherical bearings are not common outside of extreme race applications. And we can understand why – the connections they form are completely solid. Which means you’ll enjoy 100% of the generated NVH. But enthusiasts and professionals are willing to pay this price for zero waster energy. Rod ends succeed at transferring all power through your vehicle’s chassis.

Plus, they’re very adjustable and offer a wide variety of options. Rod ends are available with 2-piece ends, 3-piece ends, loaded slot ends, oversized shank ends, self-lubricating liners, etc.

To avoid confusion when choosing rod ends for your vehicle, pay attention to the following:

1. Make sure the manufacture’s misalignment angle is large enough to accommodate your rod end application. If you exceed the misalignment angle, your rod ends will likely wear, bind, or even break.

2. Make sure that the rod ends have a load rating well over the operating loads you expect.

3. Use rod ends correctly. Keep in mind that they’re designed for radial load (pushing and pulling up and down) and not for axial load (pushing sideways). A rod end’s axial load should never go over 15% of its radial capacity on 2-piece units, and 10% on 3-piece units.

4. Regularly check your rod ends – they will wear down and should be replaced as needed.

Before You Choose...

Before you choose what bushings are best for you… you need to be sure of one thing, and that’s application.

It’s impossible to get everything you want out of your new bushings. You’ll have to strike the right balance between performance and NVH. Softer bushings deliver the least performance, but also absorb the most NVH. Rod ends are solid and won’t absorb and waste any energy, but they won’t absorb any NVH either. Polyurethane bushings seem to be somewhere in the middle – they bring performance, and they make your ride more comfortable.

Where you’ll find yourself on the bushing spectrum should be based on what you’ll be using your vehicle for… and what you’re willing to put up with.

Street Performance Applications

Most enthusiasts fit in this group.

If you take out your car only a couple of times a month to enjoy it, but want a sportier ride – you fit in this group.

If you use your car for racing regularly, but also drive it to work – you fit in this group.

If you’re upgrading your daily driver which you also take to the drag strip or race track occasionally – you fit in this group.

In all of those cases, a stronger-than-stock bushing will work wonders. It won’t deflect as much, while still absorbing high levels of NVH for a comfortable ride. Street performance applications benefit the most from polyurethane bushings which bring both performance and comfort to the table.

But if you’re looking for more aggressive performance than polyurethane can offer, think about mixing them up with rod ends or spherical bushings. The rod ends will lower your deflection score, while the polyurethane bushings absorb some NVH.

Racing Applications

If you’re planning on dedicating your ride to racing, rod ends are the way to go. This is assuming you need your racing application for one main purpose – going fast. If this is true, any deflection is wasting power. And wasting power loses races.

Choosing the right bushings may seem daunting at first. But getting all the facts will point you in the right direction. The best way to narrow down your decision is by driving or riding in as many vehicles with different setups as you can arrange! There’s no substitute to hearing and feeling the difference between stock bushings, polyurethane bushings, and rod ends.

And finally, choose your bushings from brand names you can trust, like Rancho, Skyjacker, ReadyLift, Fabtech, and Skunk2! TdotPerformance is an authorized retailer of all brands advertised on our site, which means when you buy your new product from us it will come with the complete protection of the manufacturer's warranty.

Still not sure which bushings are best for you? Drop us a comment below and we’ll help you figure it out!